PIPE

CHOKE

USER'S

GUIDE

THESE INSTRUCTIONS ARE INTENDED AS A GUIDE

ONLY. FOLLOW THE PROCEDURES SPECIFIED BY YOUR COMPANY AND THE PIPE

MANUFACTURER.

You may also open and save this guide in pdf

format

Pipe Choke User’s Guide

1

Prepare the pipe-choke tool for operation. Be sure that

you have all parts and the proper size squeeze stops.

5

Begin to apply pressure until

the squeeze bars seat on the squeeze stops. A slow, uniform rate of pressure

will lessen possible damage to the pipe. Place the mechanical back-up lock

wedges in position and tap lightly to lock. Visually examine the squeeze-off.

6

Remove the hydraulics. The wedge

locks will keep the pipe squeezed-off and will help to eliminate

any release or tampering.

7

When repairs are completed, re-install the hydraulics and

apply only enough pressure to loosen the wedge locks. Remove the wedge locks

and slowly release the pressure. A slow reduction of pressure is as

important as a slow squeeze rate.

CHOKE USER'S GUIDE

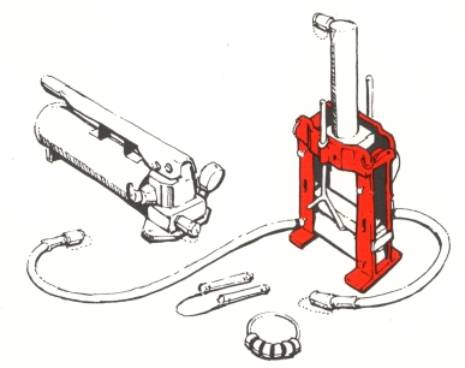

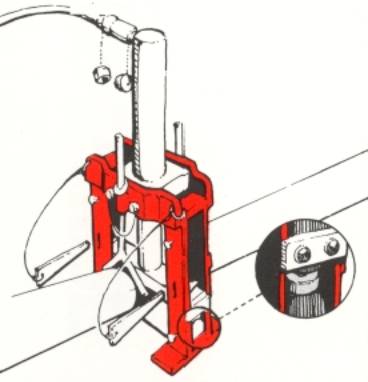

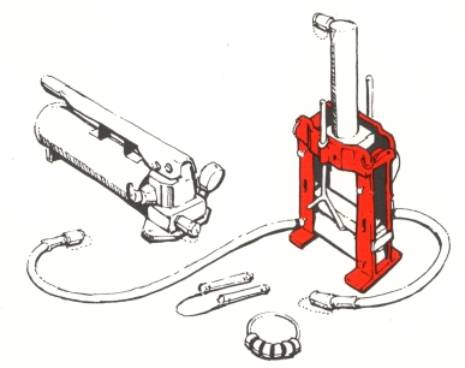

1. Prepare the pipe-choke tool for operation. Be sure that

you have all parts and the proper size squeeze stops.

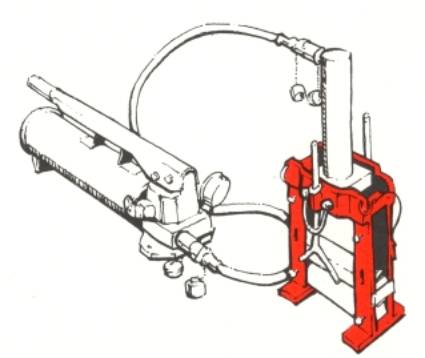

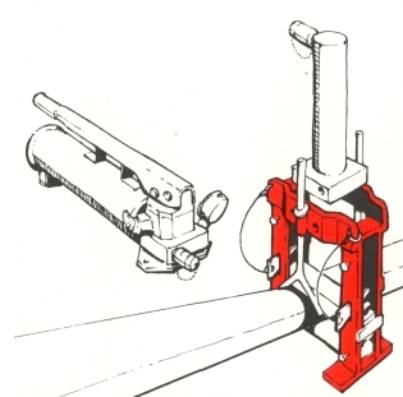

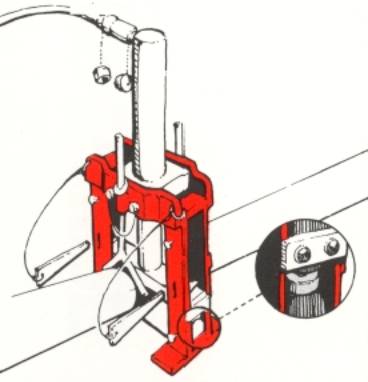

2. Assemble the squeeze unit. Visually inspect your equipment

and test it to ensure proper operation. Pipe-choke tools should be maintained

in good working order for emergency use. Examine the hydraulic hose(s) for

kinks or nicks before each use.

3. Check the pipe area that will be squeezed. DO NOT attempt

to squeeze an area of pipe that has been squeezed-off previously. Make sure

that you have enough work space for the pipe-choke and for the repair work.

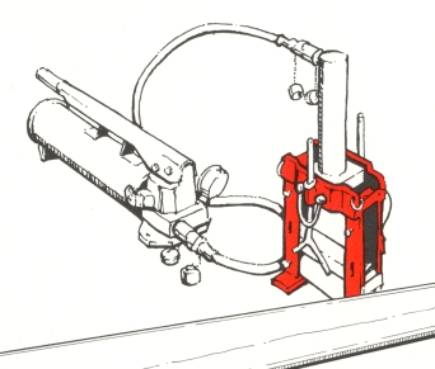

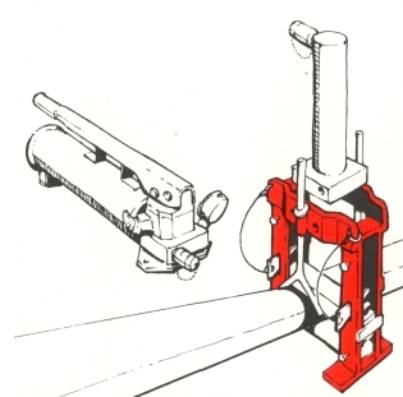

4. Place the pipe-choke tool over the area of pipe to be squeezed.

Center the machine on the pipe. Make sure the correct stops are in place

and the tool is grounded. (Follow your company's squeeze-off procedures

exactly.)

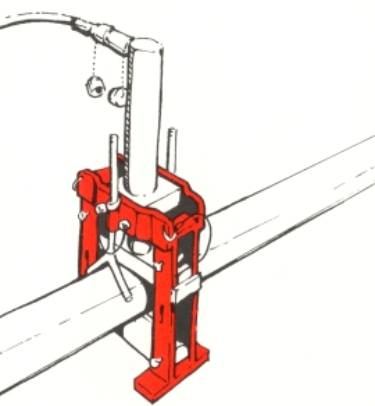

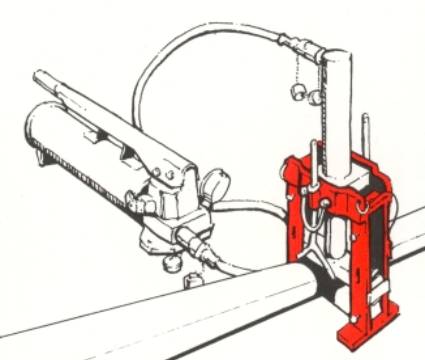

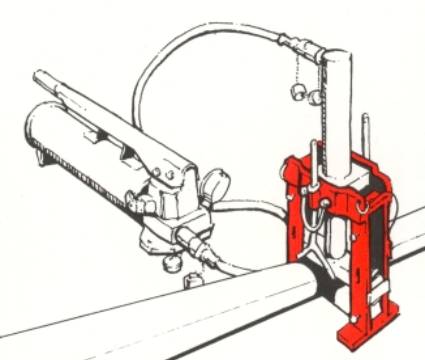

5. Begin to apply pressure until the squeeze bars seat on the

squeeze stops. A slow, uniform rate of pressure will lessen possible damage to

the pipe. Place the mechanical back-up lock wedges in position and tap lightly

to lock. Visually examine the squeeze-off.

6. Remove the hydraulics. The wedge locks will keep the pipe

squeezed-off and will help to eliminate any release or tampering.

7. When repairs are completed, re-install the hydraulics and

apply only enough pressure to loosen the wedge locks, Remove the wedge locks

and slowly release the pressure. A slow reduction of pressure is as

important as a slow squeeze rate.

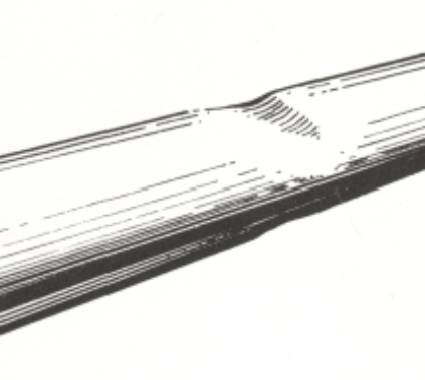

8. The pipe-choke may be rotated 90° and pressure re-applied

to re-round the pipe. Inspect the squeezed area. Report any damage immediately.

Mark the squeezed area.

9. A support clamp may be installed on the squeezed area. The

clamp will help maintain the correct pipe profile, support the squeezed section

and aid in identifying the squeezed area.

THESE INSTRUCTIONS ARE INTENDED AS A GUIDE ONLY.

FOLLOW THE PROCEDURES

SPECIFIED BY YOUR COMPANY AND THE PIPE MANUFACTURER.

Stainless

Steel Marker & Rounding Clamps Available For Use With Pipe Chokes

Heating Irons Repaired and Teflon Coated

1-800-258-7899 724-457-6193